PCB PRIME Products

PCB Prime offers everything you need to bring your electronic hardware to market on-time and under budget. We have decades of experience and the best customer service in the industry. Call or contact one of our PCB experts today!

-

PCB Prime offers the highest quality printed circuit boards at the most competitive pricing.

Whether you need a few quick turn PCB prototypes or mass production, our world class manufacturing can meet your specialized PCB needs.

-

Need a full turn-key assembly solution?

We offer quick turn prototype USA based assembly as well as high quality offshore assembly when bottom line cost is paramount.

-

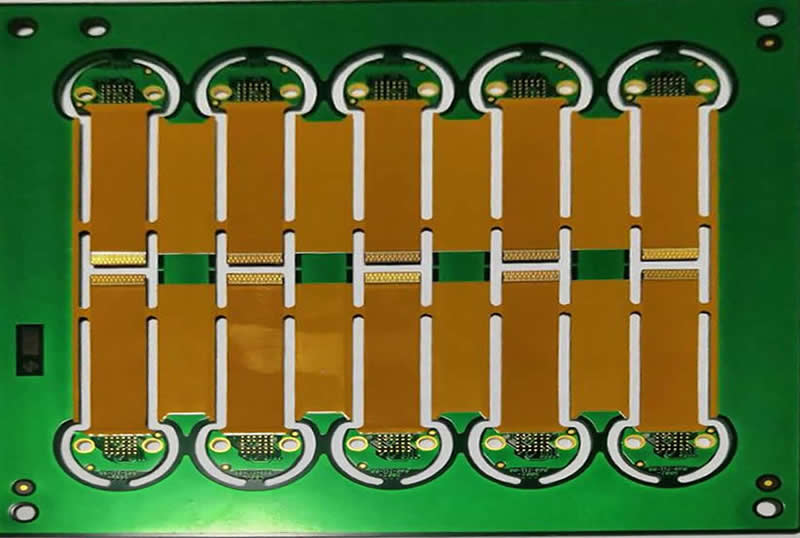

Flexible circuits are increasing in popularity. They make assembly quicker, easier and your product will be more reliable in the long term when traditional cables are replaced with a high-quality PCB Prime flexible circuit.

We manufacture everything from simple

1-layer circuits to high tech rigid-flex. -

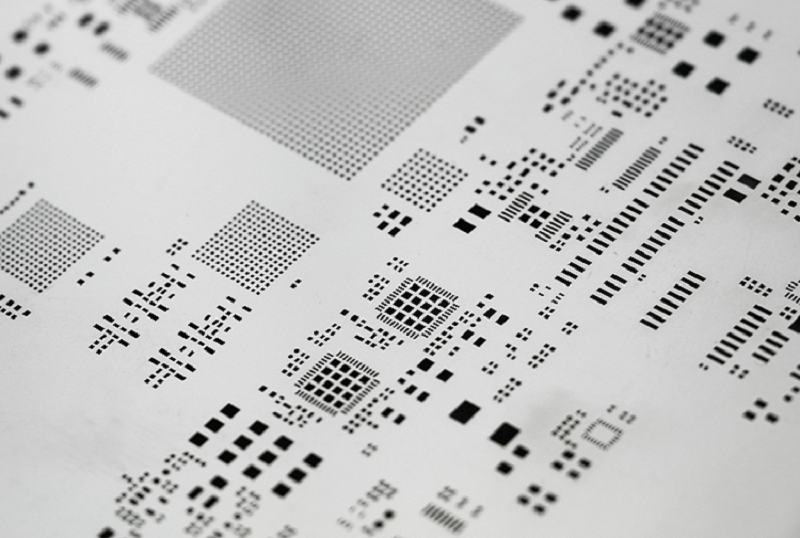

Want to assemble your boards yourself? No problem! We can also manufacture your stainless-steel solder paste stencil.