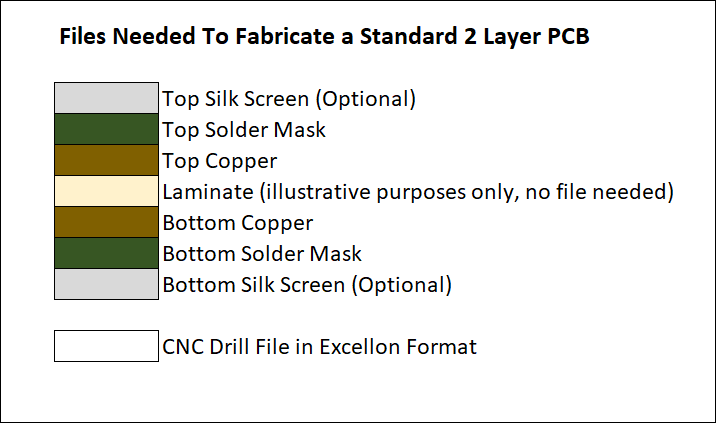

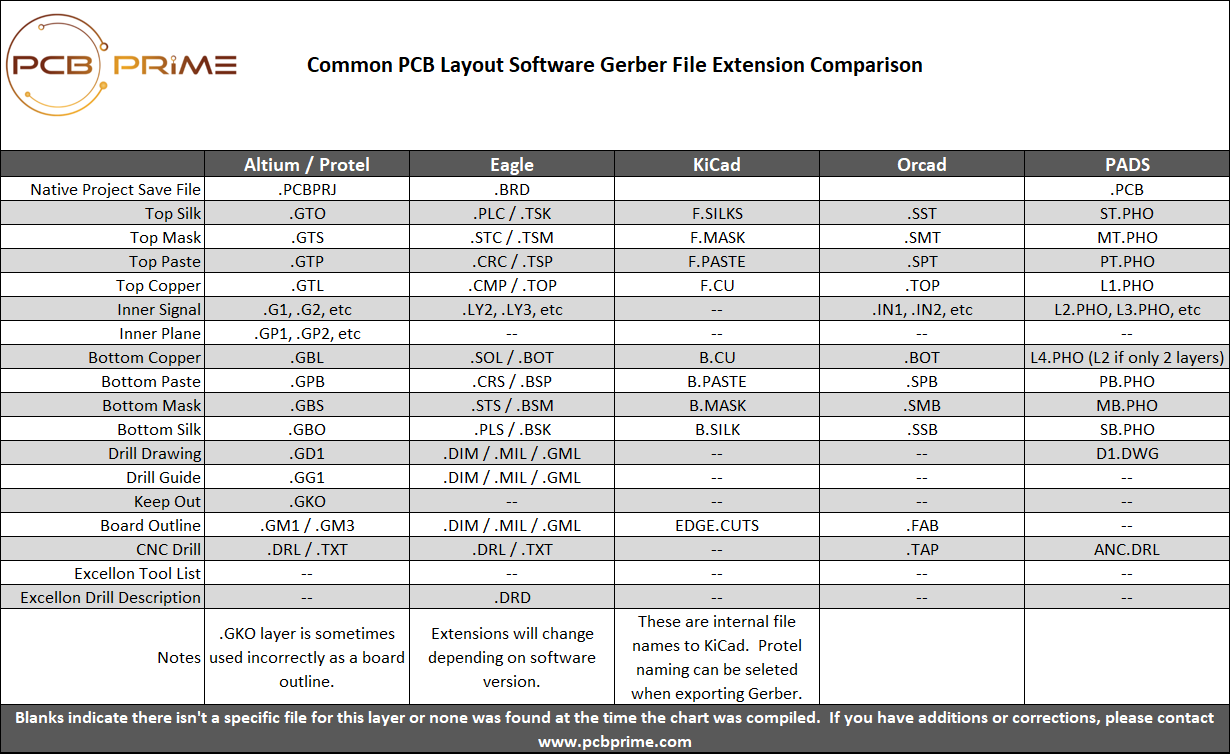

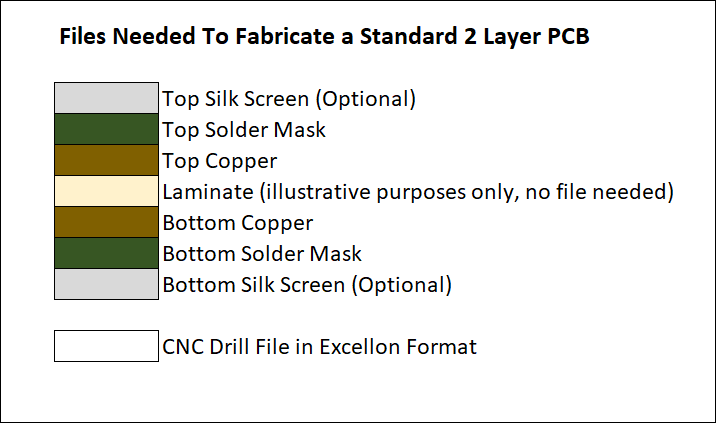

At PCB Prime, we can accept a variety of file formats to manufacture or assemble your printed circuit board. A list of accepted formats is listed below. Click the link to take you to a more in-depth explanation of each option. We'll be glad to answer any

read more...

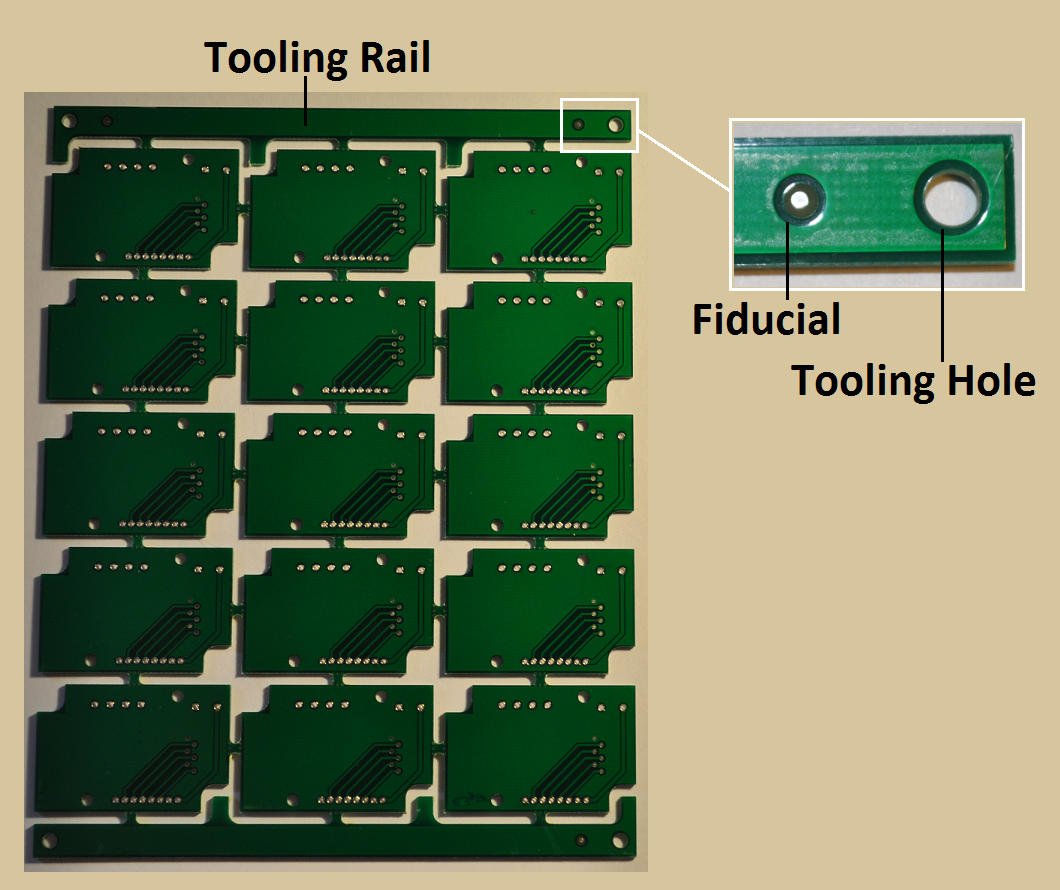

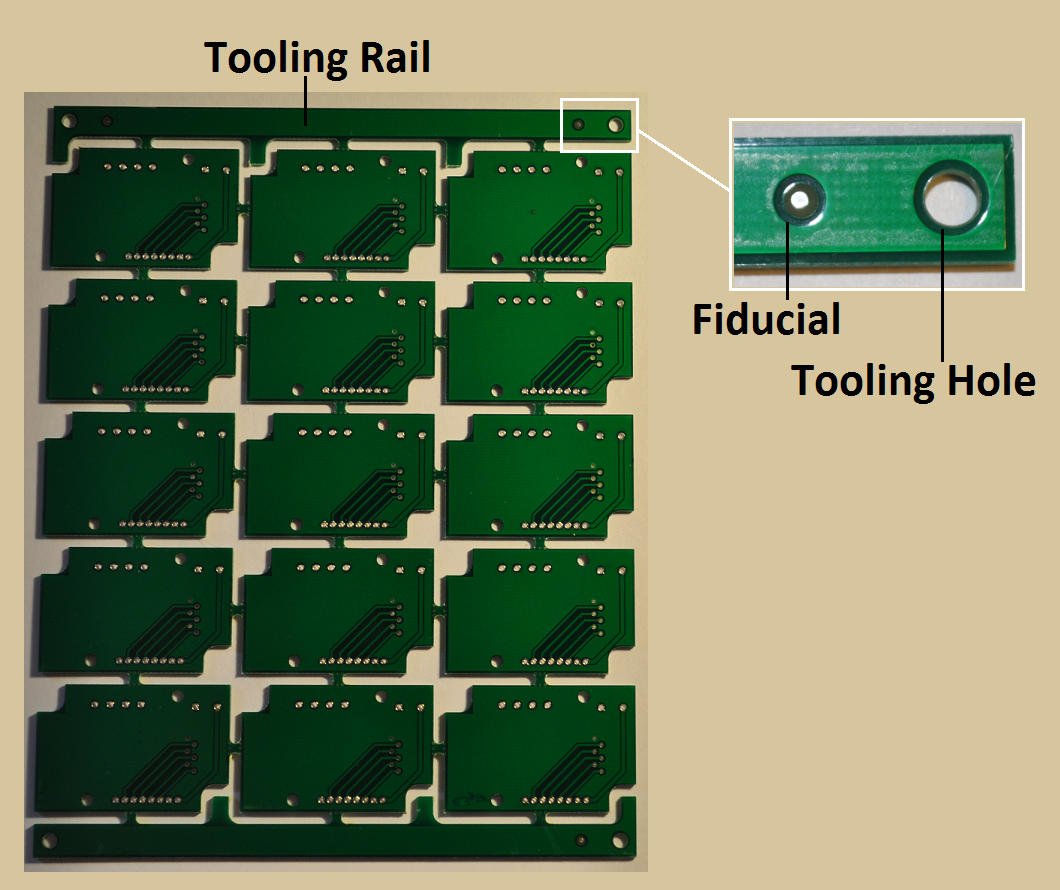

The primary reason for having your boards delivered in an array is to make automated assembly faster and less expensive. Running an array of boards through a pick-and-place machine is far more efficient than sending them through one at a time. Arrays are

read more...

When we receive artwork for a printed circuit board, many things are checked and adjusted to ensure the board is fabricated as closely as possible to the original design. If we notice something that appears unusual, we'll hold the order and question

read more...

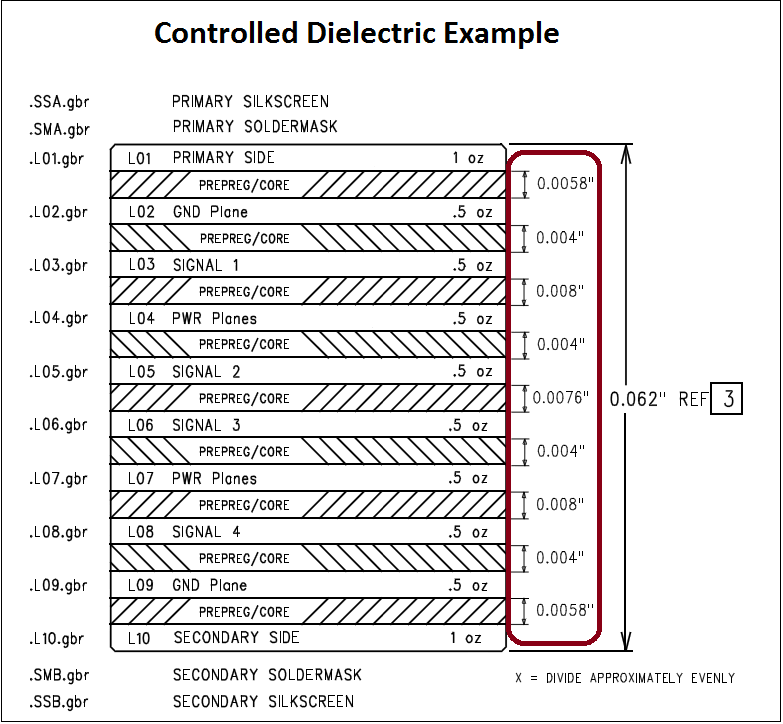

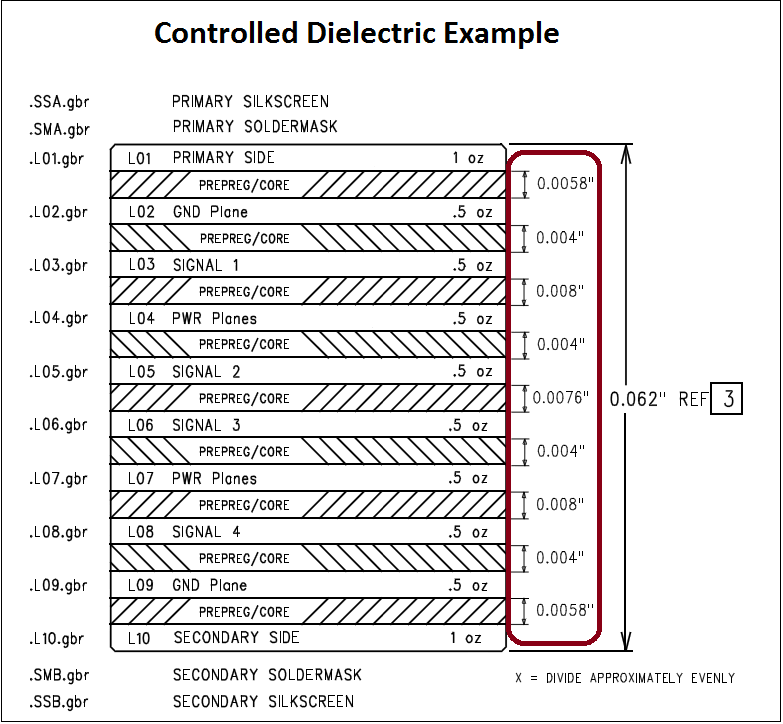

What is the difference between Controlled Dielectric and Controlled Impedance regarding PCB fabrication? The purpose of controlling dielectric or impedance is essentially the same, to achieve a target impedance on one or more signal lines on a printed

read more...

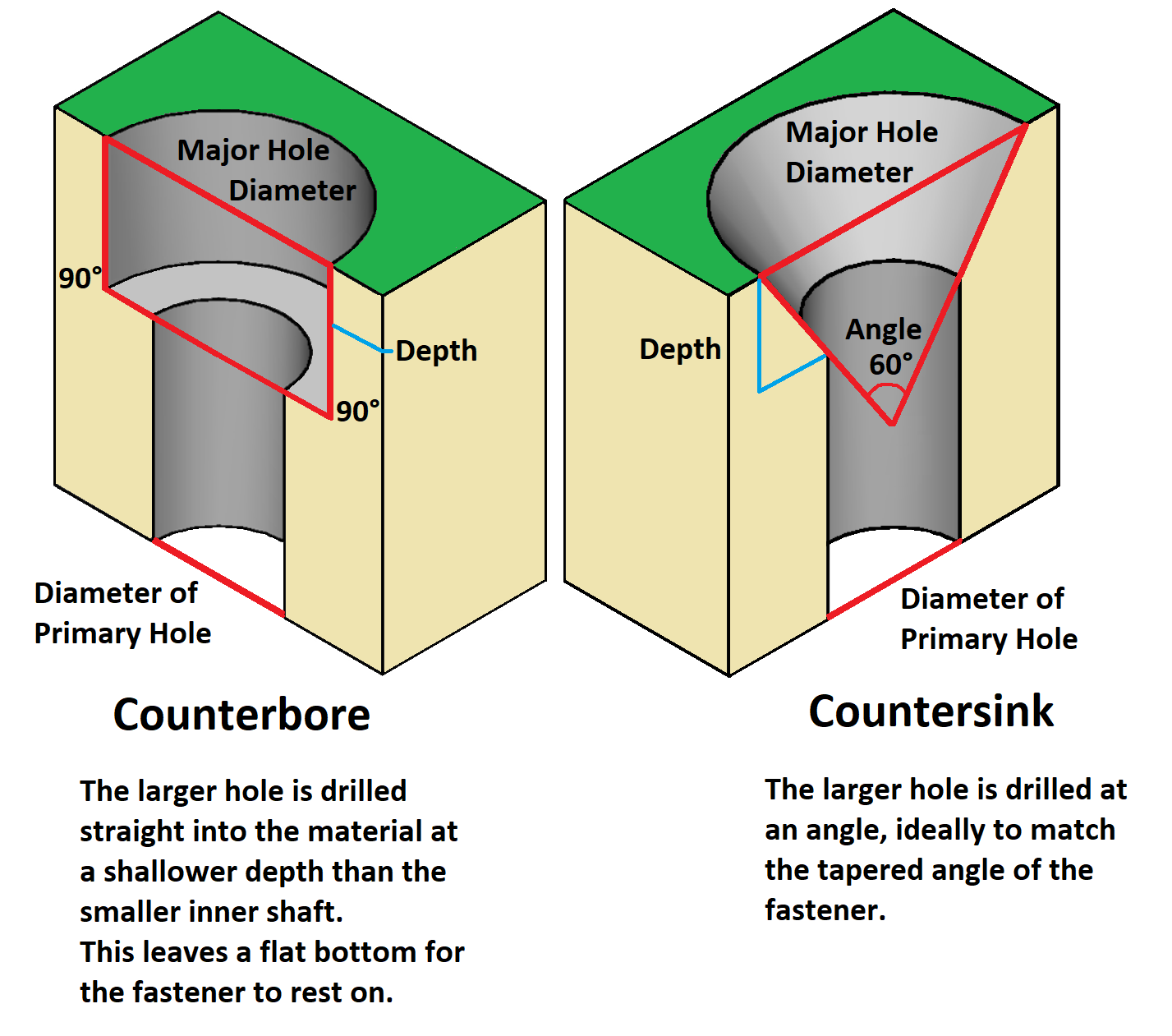

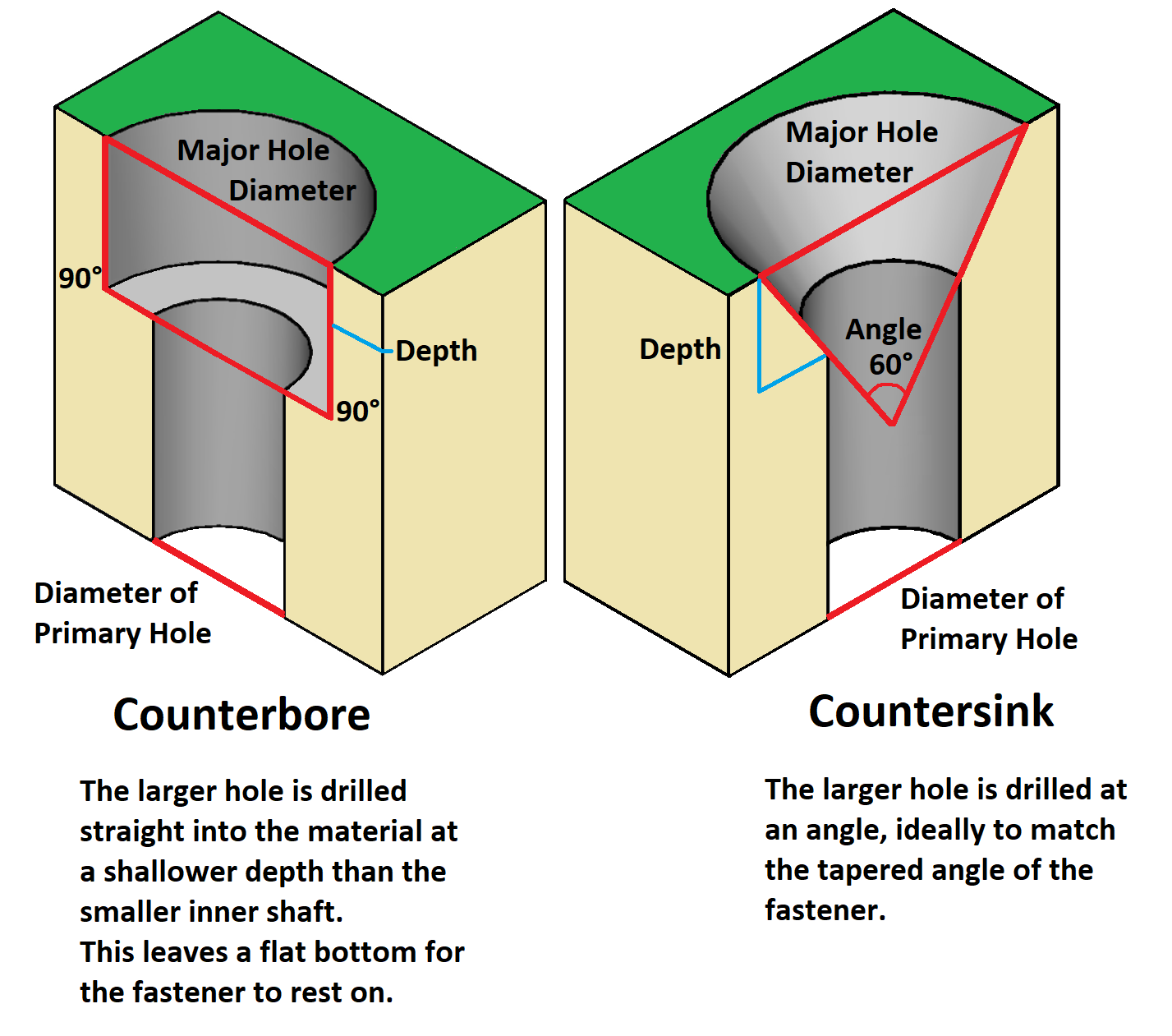

Countersinks and counterbores serve the same purpose, to allow the head of a screw or other fastener to lie flush with, or just below the surface of the material they are inserted into. The difference between them...

read more...

When we are given no other information, we will assume the following industry standard specifications. Of course, we'd rather not make assumptions, so even if these standard specifications match how you'd like your PCB constructed, it's always a good idea

read more...

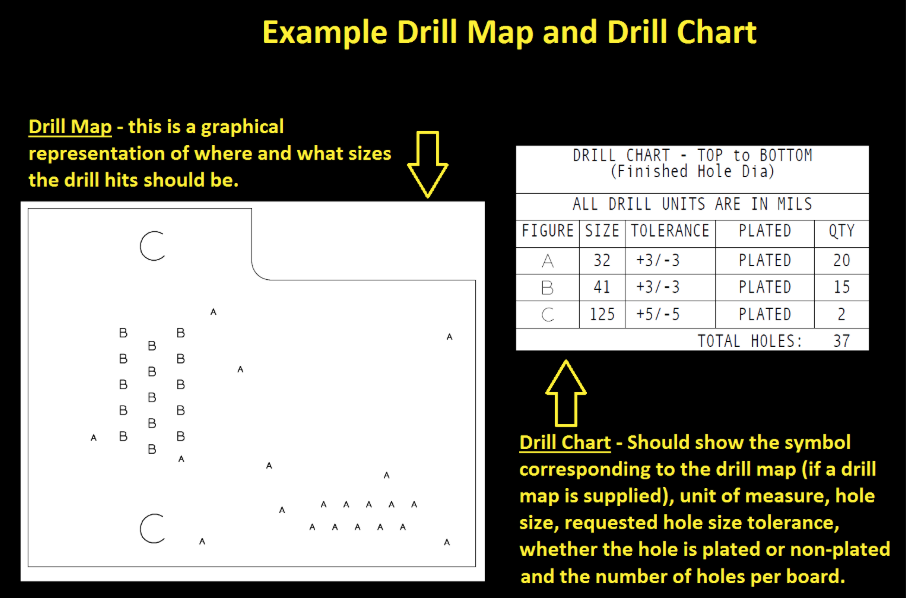

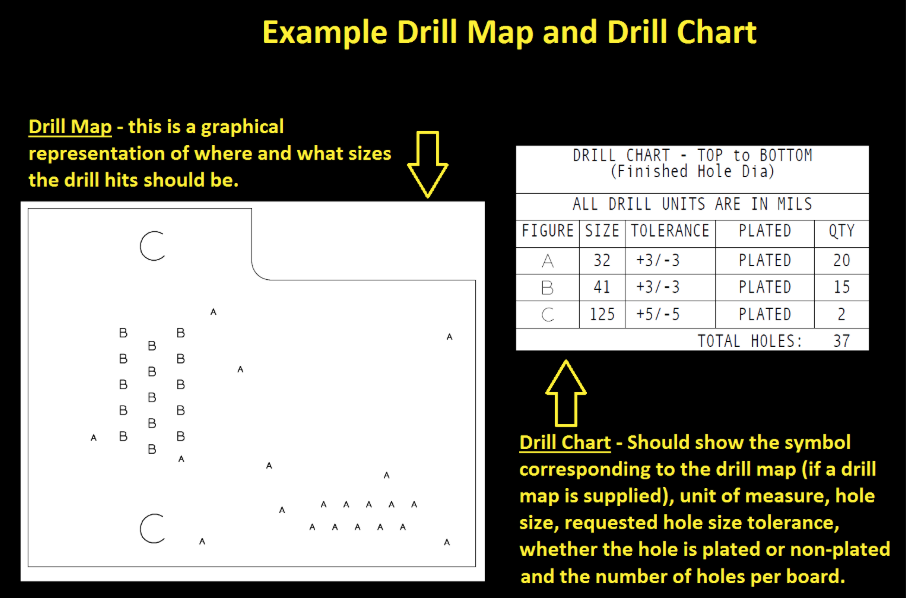

What is the difference between a hole and via on my printed circuit board? Essentially they are the same thing and many engineers use the terms interchangeably.

read more...

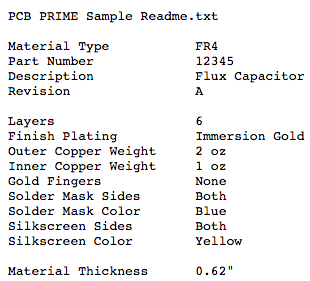

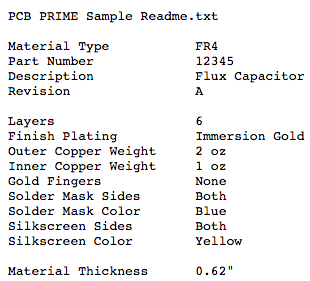

At PCB Prime, we don't require a fancy fabrication drawing. A simple readme.txt works just as well. We can accept just about any standard format for your fabrication notes. Popular fab print file types we can use are:

read more...

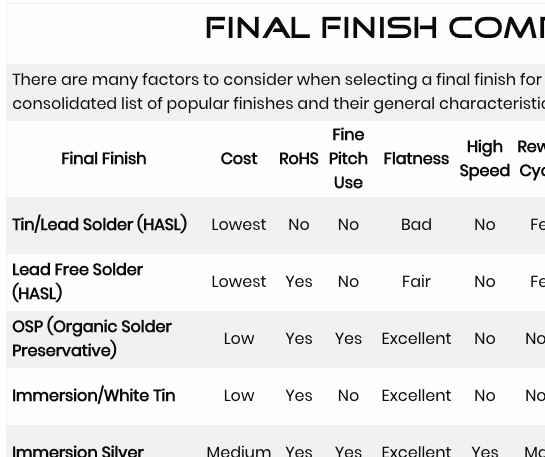

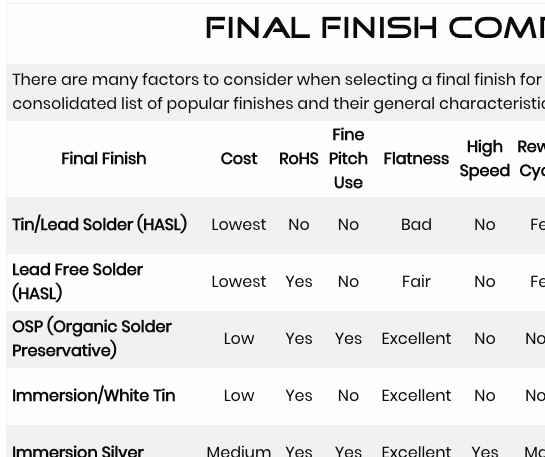

There are many factors to consider when selecting a final finish for your printed circuit board.

read more...

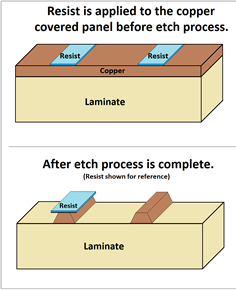

In the printed circuit board industry, the most common way to express copper thickness on a PCB is in ounces (oz).

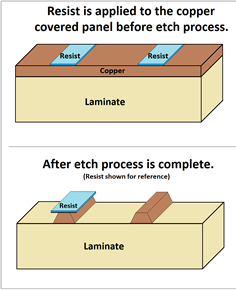

read more...

Below are common omissions and errors that we routinely find when reviewing printed circuit board design files for fabrication. Before a PCB can begin the manufacturing process, a CAM engineer must review the data submitted and make sure all necessary...

read more...

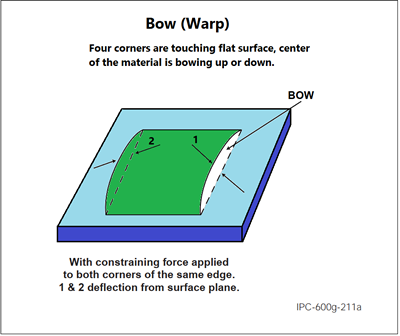

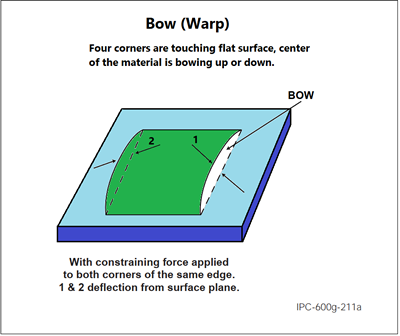

Ideally, your PCB should be perfectly flat, however, this is not always possible. IPC has defined the acceptable limits a PCB is permitted to bow or twist, this is defined in IPC-A-600 under section 2.11. Below is an excerpt from IPC-A-600 section 2.11.

read more...

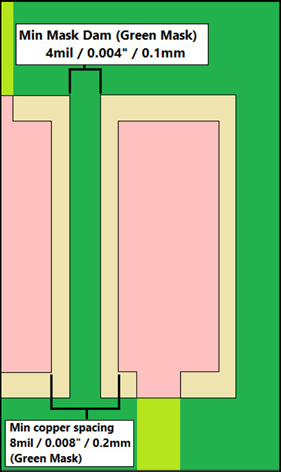

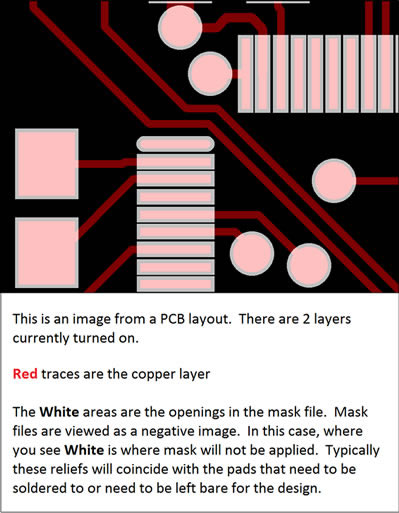

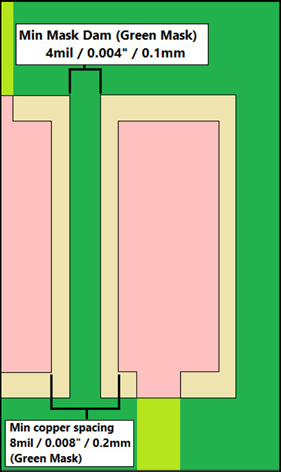

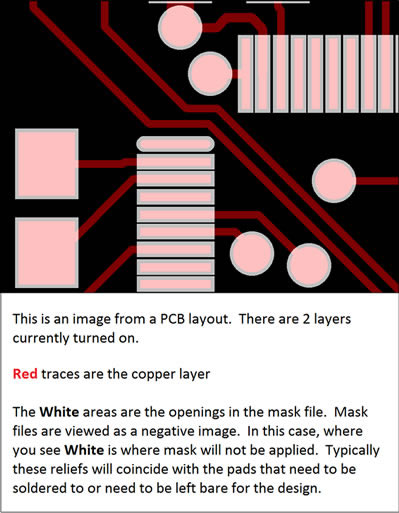

Solder Mask is a protective coating applied to the bare printed circuit board. Bare boards are covered with mask to prevent accidental solder bridging during assembly and to help protect the board from the environment.

read more...

There are many reasons a printed circuit board designer might want to have a via tented, plugged or filled. First, let's start with defining these terms since they can be frequently misused and misunderstood.

read more...

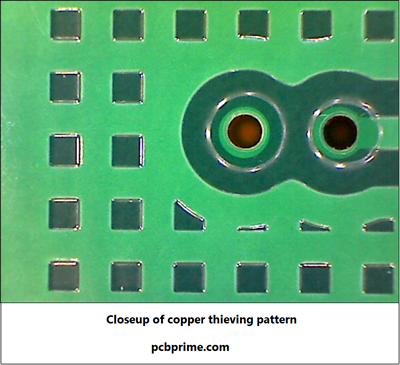

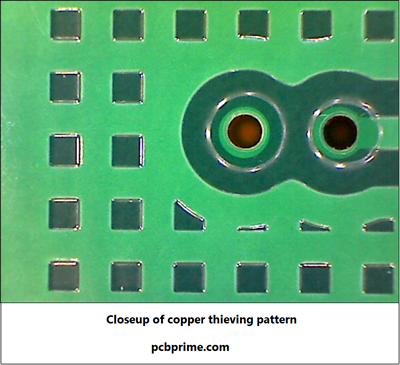

Copper Thieving is just a fancy way of saying that small copper circles, squares or even a solid copper plane will be added to larger blank spaces to even out the copper distribution across a copper layer. The added copper isn't connected to any nets on

read more...