Holiday Update - Chinese New Year 2026 -- Year of the Horse.

Please be aware our primary factories will be closed in observance of Chinese New Year, 2/7 - 2/24. These days will not be included in order lead times. There is still some capacity to ship before the holiday but that window is closing quickly.

We also have domestic manufacturing options, please contact us for a domestic quote.

Please contact us if you have questions about how this may impact the delivery of your order.

Thank you, PCB Prime

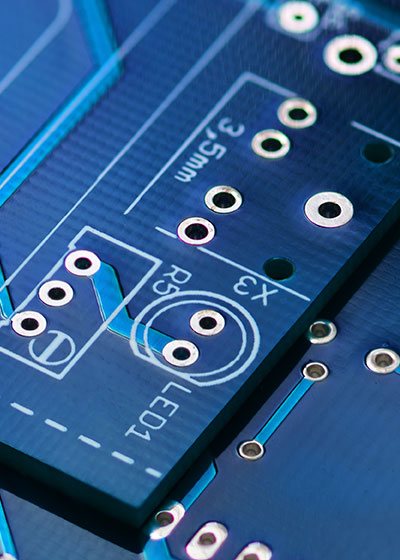

High Quality, Low Cost

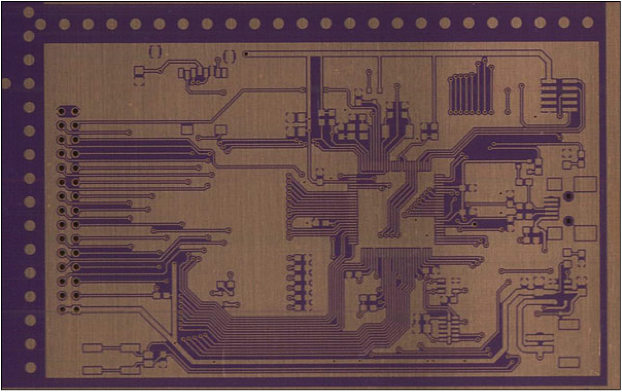

Printed Circuit Boards

Click here for an instant quote

If you prefer to send us your files for a quote, or if you have manufacturing questions, please call us toll-free at 800.791.5370 or contact us. We will be glad to help!

Rigid PCB capabilities

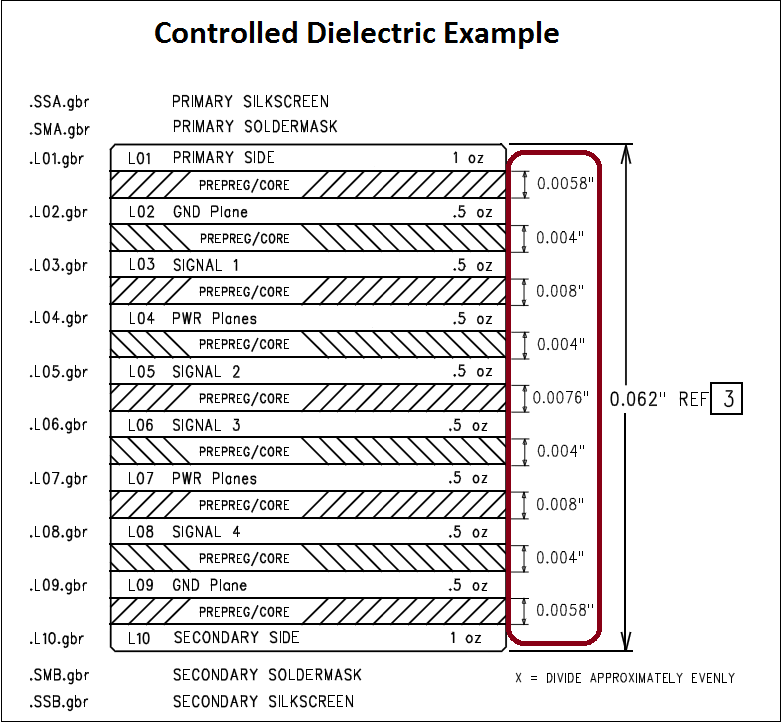

- Up to 42 layers

- FR4, Aluminum, Rogers, Nelco and more

- Controlled Impedance

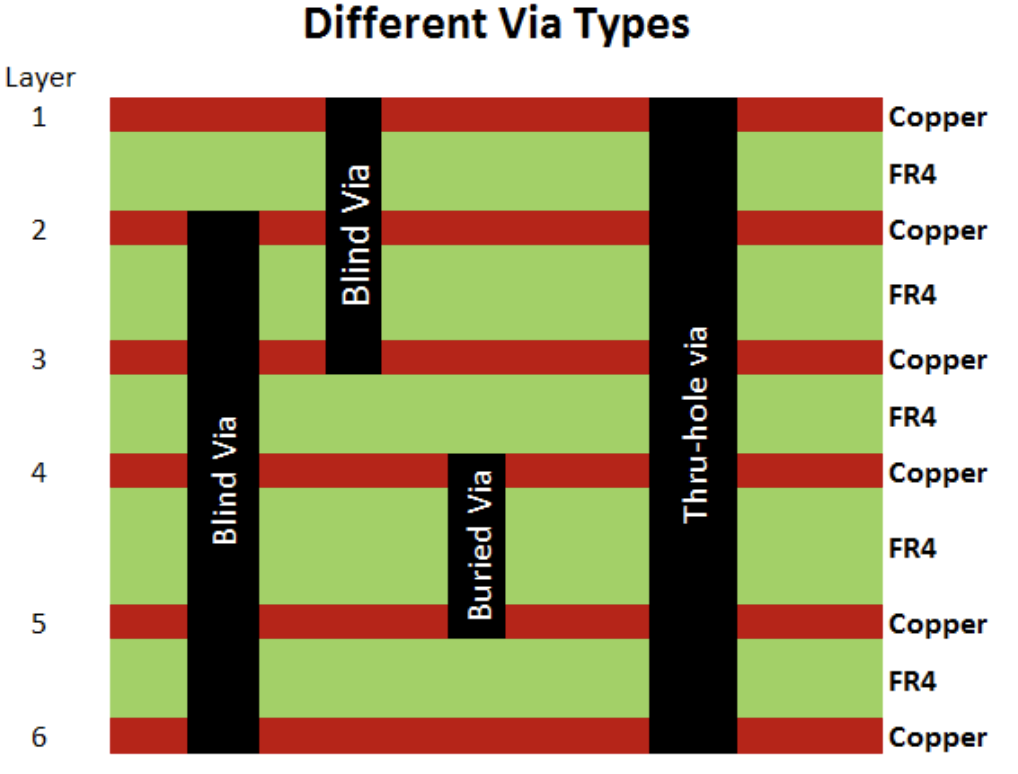

- Blind & Buried Vias (HDI)

- Via In Pad / Active Pad

- Class II & Class III

- ISO 9001:2015

- RoHS and REACH Compliant

PCB Assembly Services

- Fast Turn Times

- Turnkey/Kitted/Consigned

- Surface Mount (SMT) / Thru-hole

- Single- or Double-sided Placement

- Lead or Lead-free

- BGA

- Fine Pitch

- X-Ray

- Functional Testing

PCB PROTOTYPE SERVICE: SPECIAL PRICING

No hidden fees

Our PCB prototype service offers special pricing perfect for hobbyists, students or multi-million dollar corporations looking to get a quick and simple prototype to prove their design before committing to a larger and more expensive order. Please read the details on what specifications are offered under this discounted program. If you need different specifications than what is offered, click here for a full-spec quote or contact us.

Custom PCB Manufacturer

We are committed to the continuous improvement of our services to our customers

Order with confidence; we stand behind our PCB manufacturing products and assembly products and services. We will do everything we can to be sure you are completely satisfied with your order.

Easy Quote Form

We continually look for ways to streamline and improve our online quote process so you can be confident your online quotes are accurate with no surprises after your order is placed.

Instant Pricing

Our online quote form is available to you any time, day or night. Coming soon as Assembly and Stencil quoting capabilities.

No Tooling or Test Charges

We never charge tooling so you can change revs as often as you need. We electrically test all our boards at no additional cost to you.

No Hidden Fees

Tired of 'handling fees...', whatever those are? We never charge additional fees. Your online quote is the total cost of your order plus the shipping method of your choice.

Proto and Production

We process all size orders from 1 piece to 1,000,000 pieces. We can handle your proto and full-scale production needs.

Fast Lead Times

Need boards in a hurry? We've got you covered. Depending on the size and specs of your order, we can ship in as little as 2 business days and be on your doorstep on the 3rd day.

World Class Quality

Our manufacturing partners are some of the best in the world. We can build just about any design you can dream up; we've seen it all.

ISO and UL Certified PCBs

All of our manufacturing partners are at a minimum ISO 9001:2015 and UL certified.

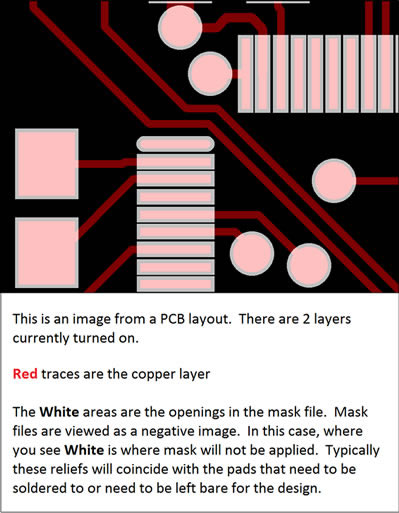

PCB Tips

Helpful tips for your next project

New tips are added all the time; check back occasionally to see what's new.